-

Phone

86-595-8****

-

Address

-

E-mail

LatestProducts

Qft10-15 Brick Making Machine Price List

China Qft10-15 Brick Making Machine Price List, China Brick Making Machine Price List, China Block Brick Making Machine

Description

Basic Info

- Model NO.: QFT10-15

- Customized: Non-Customized

- Type: Vibration Molding

- Frame Dimension(mm): 8700X2500X3020

- Exciting Force(Kn): 100

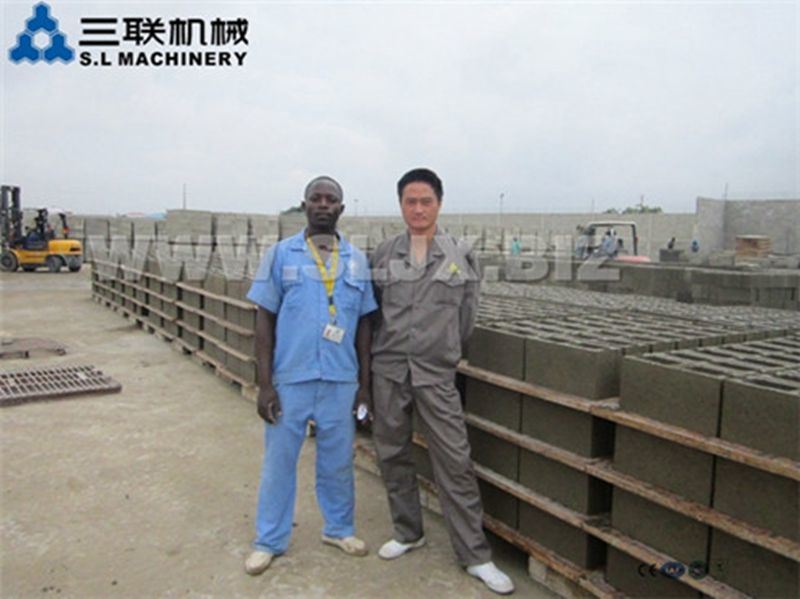

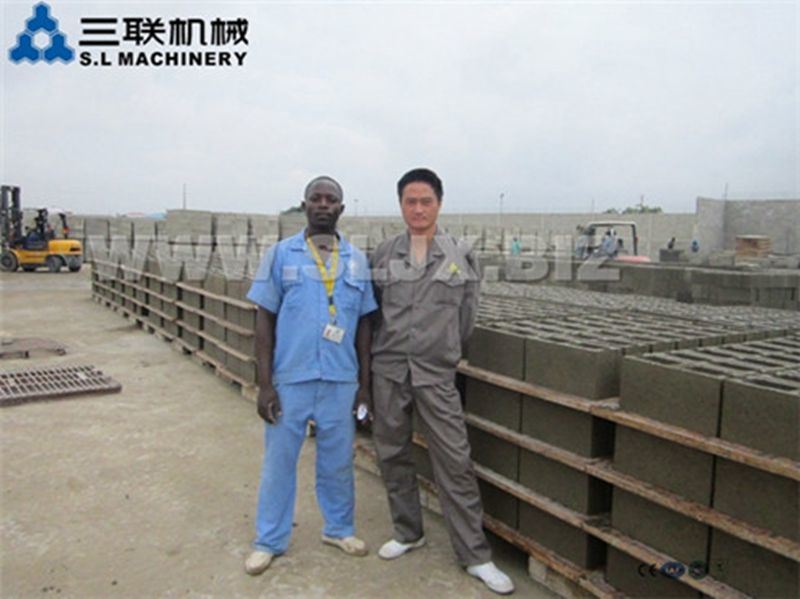

- Trademark: S. L MACHINERY

- Certification: CE, ISO

- Automatic Grade: Automatic

- Color: White/Blue

- Control Mode: Full Automatic PLC Control

- Bamboo Pallet(Lxwxt): 1220X900X25

- Origin: Fujian, China

Product Description

Block machine QFT10-15

1. Raw material: Crushed stone, sand, cement, dust and coal, fly ash, cinder, slag, gangue, gravel, perlite and other industrial wastes.

2. Applied products: Concrete blocks. Solid / hollow / cellular masonry products, paving stones with or without face mix, garden and landscaping products, slabs, kerbstones, grass blocks, slope blocks, interlocking blocks etc.

3. Applied fields: Widely used in buildings, road pavers, squares, gardens, landscaping, city constructions etc.

1. Raw material: Crushed stone, sand, cement, dust and coal, fly ash, cinder, slag, gangue, gravel, perlite and other industrial wastes.

2. Applied products: Concrete blocks. Solid / hollow / cellular masonry products, paving stones with or without face mix, garden and landscaping products, slabs, kerbstones, grass blocks, slope blocks, interlocking blocks etc.

3. Applied fields: Widely used in buildings, road pavers, squares, gardens, landscaping, city constructions etc.

Q(F)T10-15 Block Making Machine

Technical Data

|

Technical Parameter

| |||||||||||||||||||||||||||||||||||||||||||||||